Keg exterior

We offer the following services for kegs which have been rejected in the filling plant or which come from other supplies and no longer fit in the standardised series:

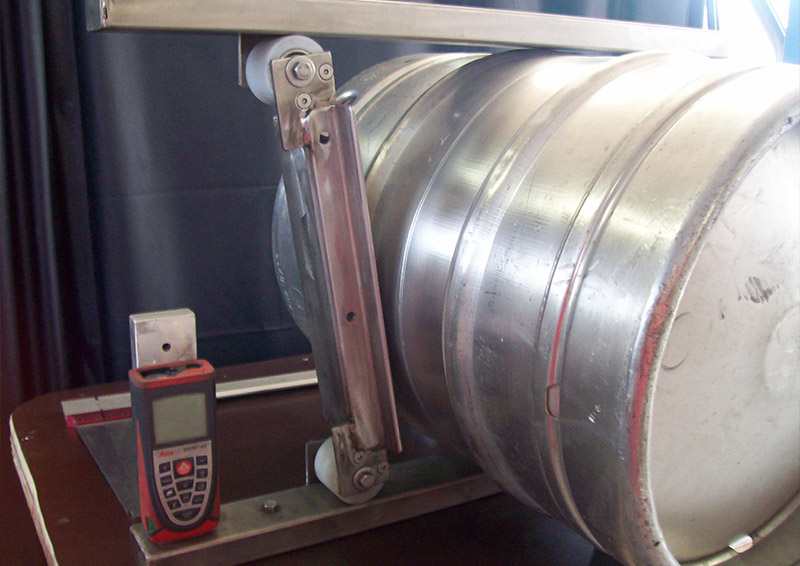

Dent removal of top and bottom chimb

To ensure your keg passes through the filling plant efficiently, we repair the top and bottom chimb using our patented dent removal machine, achieving unique results in terms of dent removal quality.

Our uniquely working Keg Roller for the purpose of removing any damages in keg chimbs is able to put them back to its perfectly round original shape within less then a minute.

When very large numbers of kegs need to be repaired in a relatively short period of time we recommend two machines in operation, simultaneously handled by just one person, in order to work extremely time and cost efficiently.

This process in addition is not only safe but even strengthens the stainless steel material of the chimb!

Adjusting Keg Necks

To ensure the filling heads can be connected without any problem, we use special tools to set the keg necks to a deviation of less than 2°.

The distance between the internal bottom of the keg to the neck is set to the required height by hydraulic tools.

Necks are straightened to the optimum level by manual tools and furthermore threads can be re-cut back for easy and tight spear fitment.

Finally, the neck diameter can be adjusted to the original standard!

Removing labels and cleaning rounded surfaces

If an old label needs to be removed from your keg, we have developed high-pressure water cleaners and polishing machines which can remove all materials from the keg.

With high pressure (350 / 400 bar) and hot water (90°C – 100°C) we can eliminate not only banderols but also rust, all kind of adhesive residues and labels.

Polishing

To make the freshly refurbished keg shine we use Surface polishing by special fleece Machinery.

Regardless, if dealing with rust, old adhesive stickers or any other type of dirt on the keg, our mobile polishing unit will clear, clean and shine up every keg surface.

For this service no chemicals are being used and the stainless steal surface stays without roughening!

Repairing rolling rims

If your keg’s rolling rims have been getting flatter over the years and the kegs cannot be properly gripped by the robot or forklift, we can use our patented machines to restore the old rolling rim without affecting the keg.

Welding Chimbs

We have trained MIG and TIG welders who can repair all welding work on your keg using high-tech welding equipment.

Our qualified staff will weld broken chimbs, leaking necks and holes in the kegbody of your stainless steel or aluminium kegs.

Herewith we are overcoming the sharp edges and the neck stays stable after welding.

Chimb – Seam – Welding without body contact and damage!

Application of the Colour Ring

Herewith we want to offer our brewery customers an effective and quick solution, to mark kegs cost-efficiently in high daily output!

In cooperation with our partner, who enables a much wider range of colors, we apply different colours on the keg surface.

We guarantee high resistance and durability with long-lasting effect!

Rebranding: Neutralisation

We can neutralise engraved brewery names on the keg using a hydraulic machine.

If you are planning to sell your kegs we have an in-house developed machine which will emboss a waffer-like pattern over the brewery name into the chimb, which therefore will neutralise the keg.

Those machines are built for the purpose of being operated as a mobile unit and have a capacity of 50 names per hour.

Rebranding: Marking of brewery names and brewery logos

Using our on-site marking service we are able to label the kegs permanently in a dark hue and in any desired size.

By means of our electrochemical process the marking is distinctly more durable than conventional painted labelling.

In conjunction with our neutralisation service you can therefore clearly demonstrate who your kegs belong to.

Rebranding: Shield plate attachment

In collaboration with our partner we provide metal shield plates in various sizes and attach the new branding on the chimb of the keg.

With new shield plates old brewery name can be covered so that no additional waffer-like pattern has to be embossed into the chimb.

Rebranding: Embossing of a Brewery name

With our in-house developed hydraulic machines we emboss a brewery name in letters on the keg-chimb.

This service will enable our brewery customers to brand the newly purchased kegs in different font sizes.

Correcting neck diameters

If your kegs have different neck diameters, we can standardise these using equipment specially developed by us.

Keg Transponder Attachment

With an inhouse designed weldingmethod we attach tags (transponders) longlasting to your kegs.

If requested, we will supply conveyorlines and bypassunits for trans ponder attachment online, during keg filling production in the brewery plant.

Advantages:

- Fast logistic collection and processing of data due to bulk & touchless scanning

- Minimizing keg-loss

Keg height adjustment

For Keg-pool projects we are offering the service of keg height adjustment.

With our equipment we are able to reduce kegs with approx. 20mm higher height to an acceptable degree and adjust the stackable feet chimbs to the desired diameter!

Herewith keg stocks can be standardised in their outer form and can be handled without complications both in logistics and in the filling line.