Keg interior

We offer the following cleaning and repair services to meet the high hygiene standards of keg interior surfaces:

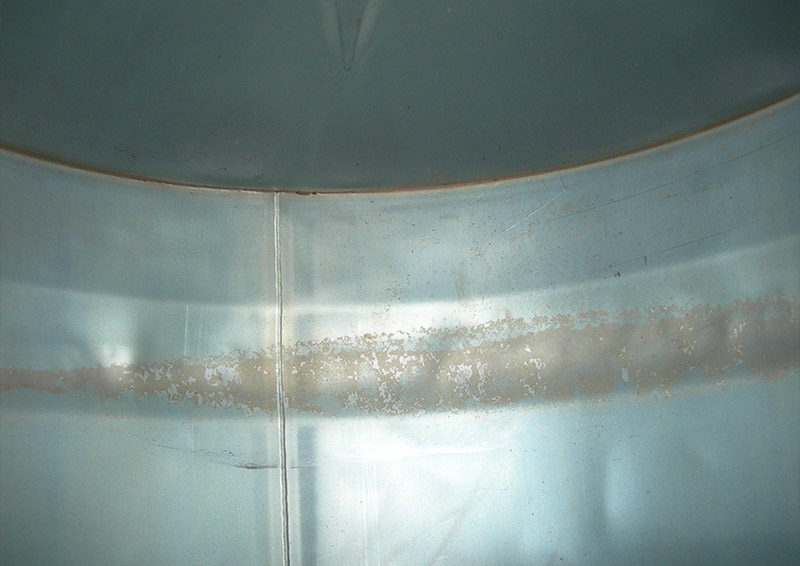

Removing beer scale and mould in the keg

We can remove undesirable beer scale and mould using special cleaning solutions, and then neutralise them with a rotary nozzle system.

To do this, we use 80°C – 90°C water with a working pressure of 200 – 300 bar.

Application of special cleaning solutions with a full coverage up to the neck upper edge to reach the full cleansing effect!

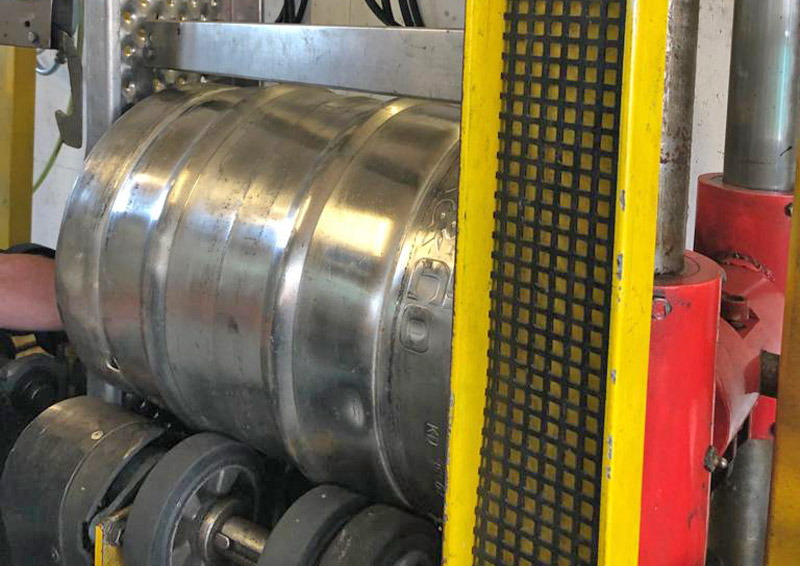

Removing dents from keg body and adjusting the sump pan size

If the body of your keg has a volume-reducing dent, we can remove this using hoisting technology. If the keg neck is no longer at the correct height, we have hydraulic tools to restore the sump pan size.

Pressure test on the keg body and spear

To ensure the keg body and spear is still pressure-tight after the repairs, we always conduct an underwater pressure test once the work has been completed.

Leakage of spears or of the kegbody are localised by pneumatic pressure test!

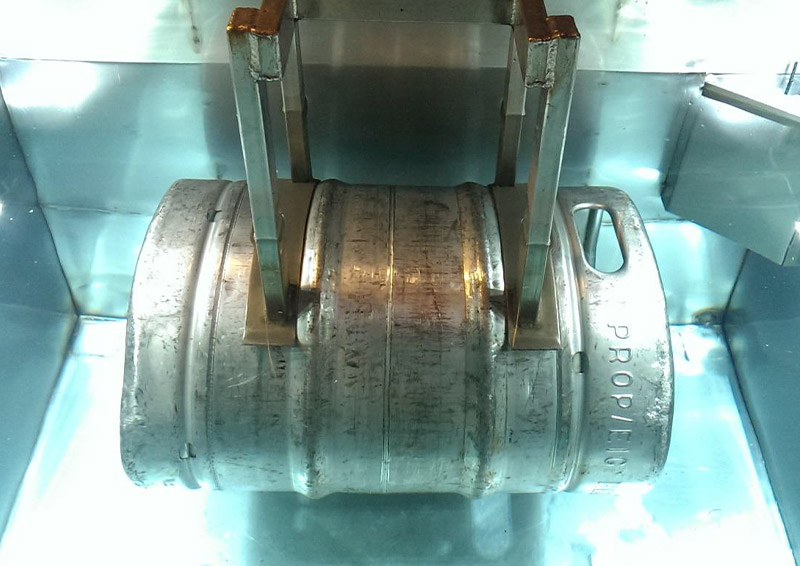

De-denting of the base cup

With this service we have employed a technique which remoulds the battered base cup to its original condition without having an adverse effect on the inner surface quality. The original sump depth is thereby restored and the fitting can easily be inserted.

Internal Keg Inspection

With inside screening, which we carry out using a hand lamp and Camera, we can examine the keg interior in detail.

Our equipment enables us to check:

- H 3 level

- Spoiling

- Contamination

- Crack

- Pitting.

- incl. Neck area.