Quality test

We determine the following keg qualities using state-of-the-art measuring equipment and working together with a material testing institute:

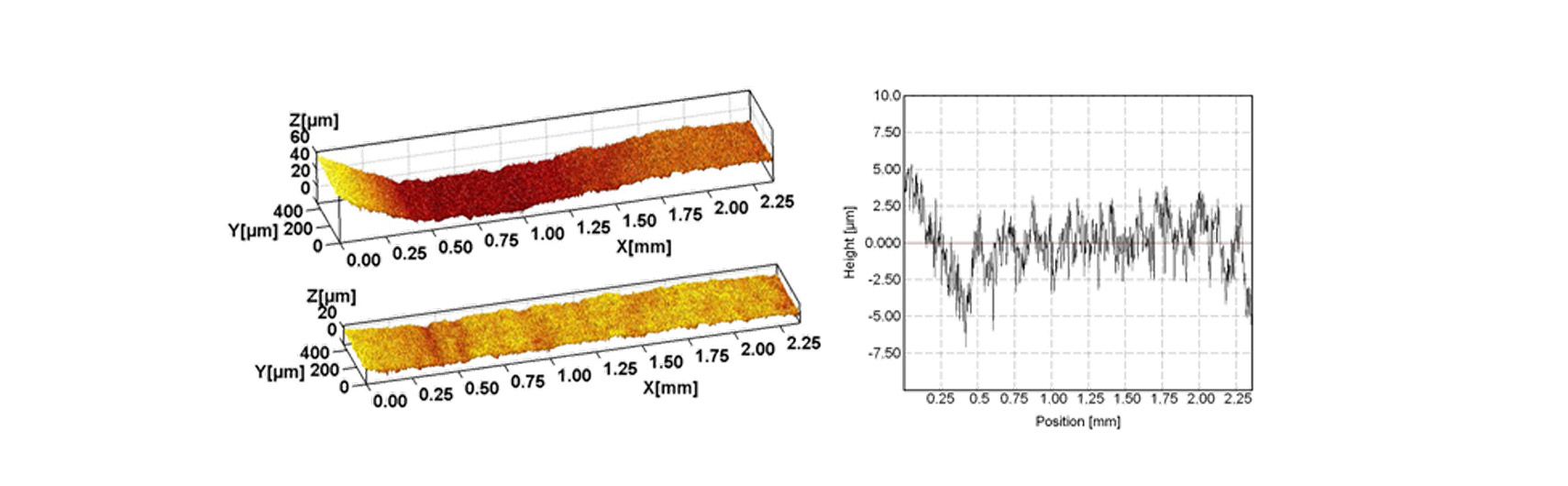

Surface analysis

The surface roughness of the material coming into contact with beer is determined in µm as per DIN 6647.

Crack tests

The kegs are cracked using special pumps, and the maximum pressure documented.

Volume calibration

The maximum volume of a used keg is determined using calibrated measuring equipment.

Material strength

The keg’s dimensional stability is determined and documented in accordance with DIN standards.