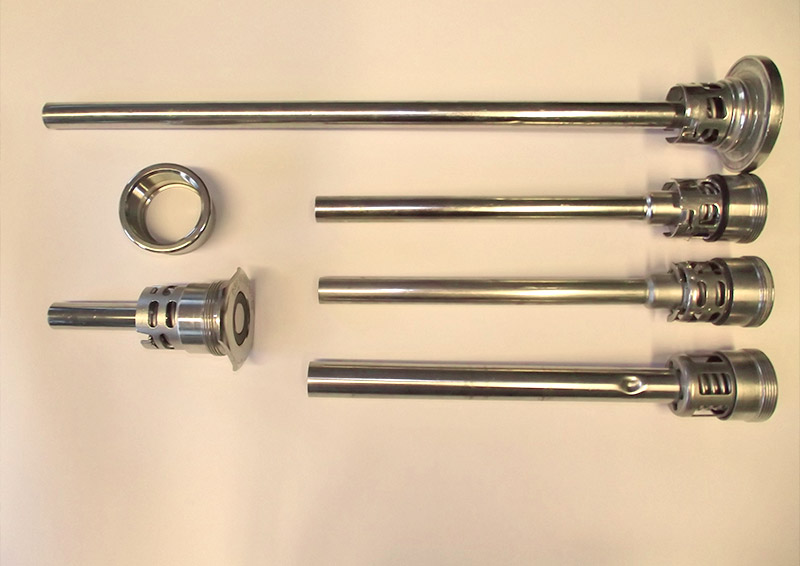

Spear

We perform the spear service at the brewery as follows, in accordance with the brewery regulations:

Spears exchange

If old spears need to be replaced, we do this using the spears manufacturer’s approved assembly tools.

We clean spears by ultrasound and refit new spear sealings, valves and malfunctioning coils, where necessary.

We refit the repaired spears, either with electronically documented or manual torque.

Replacing wear parts and cleaning stainless-steel parts

We break spears down into their individual components and clean the undamaged stainless-steel parts using a special cleaning agent.

The plastic wear parts are re-assembled and then subjected to a pressure test.

Our very experienced staff document this work in a computer system.

Spear Shortening

On request we can shorten the 50L – Spears to your desired size (30L, 25L, 20L)!

Additionally, we want to offer you a complete overhaul of the spears.

As a result you can have your 50L-Spears converted to the desired sizes in almost new condition!

Spring Check

In addition to our main spear repair services we also carry out testing of the compressive force of springs.

We adjust the spring performance in line with the manufacturer’s specifications!